Cordless Drill Evolution: End Battery Platform Anxiety

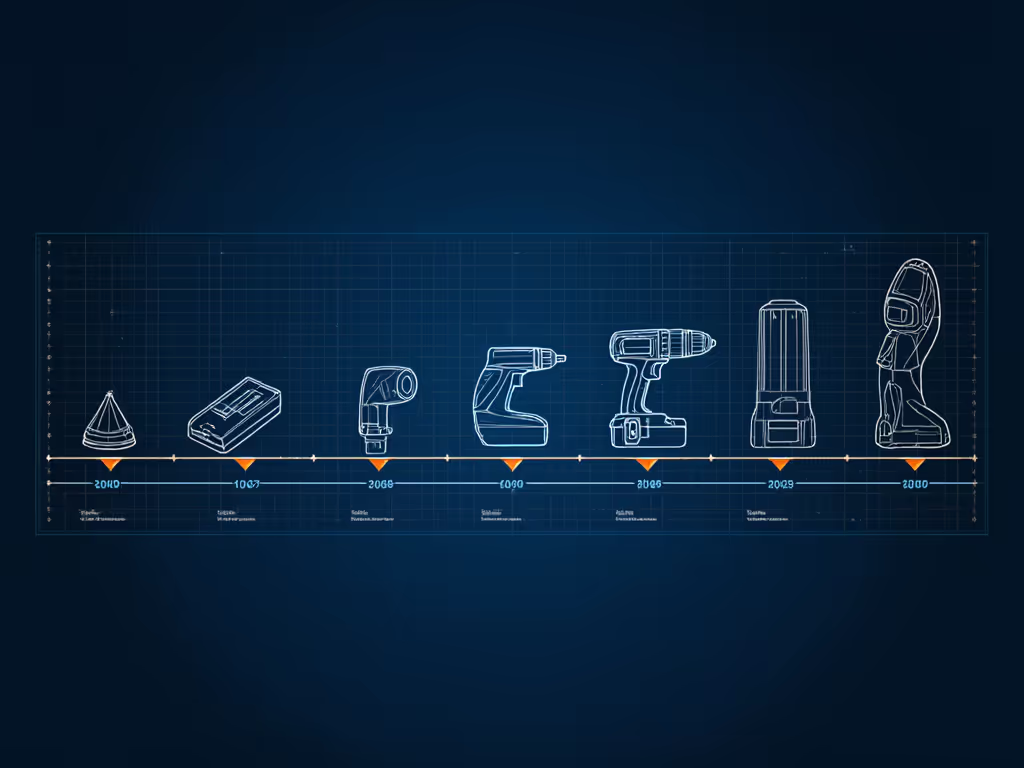

As a community makerspace instructor, I've seen how cordless electric drill anxiety paralyzes even enthusiastic beginners. That knot in your stomach when choosing platforms? It mirrors our tool's own journey (from clunky industrial machines to today's agile ecosystems). The power tool evolution wasn't just about watts or volts; it was about freedom from anxiety. Let's reframe this timeline as your roadmap to confidence.

Why Your Drill History Lesson Matters Today

When Black & Decker stunned contractors in 1917 with their pistol-grip drill (inspired by a Colt Peacemaker on their desk!), it wasn't just ergonomics; they solved real paralysis. Suddenly, drills moved from factory floors to your hands. But the true revolution began in 1961 when Black & Decker introduced the first cordless drill with nickel-cadmium batteries. Industrial users got mobility, though consumers waited until Makita's 1978 7.2V model brought cordless freedom to weekend warriors. Each leap tackled the exact anxieties you feel today:

-

The Pistol Grip (1917): Solving "Heavy, poorly balanced drills causing fatigue" Before this, drills were awkward, weight-forward tools that strained wrists, especially overhead. The pistol grip shifted weight behind the motor, distributing load across your whole arm. Pro tip: If your current drill feels nose-heavy during shelf installation, check if it uses a compact front-grip motor design (common in modern brushless drills). This 100+ year-old innovation directly addresses your #1 ergonomic pain point: fatigue on ladders.

Practice on scrap; then commit.

-

Removable Batteries (1978): Ending "Duplicate chargers and battery bloat" Makita's 1978 breakthrough wasn't just cordless, it featured removable batteries. Suddenly, swapping cells meant no downtime. But early adopters faced new chaos: incompatible voltages and proprietary shapes. Today's standardized platforms (like popular 18V/20V systems) finally deliver what that first removable battery promised: one ecosystem. If you're stressing about buying three batteries "just in case," remember: modern 2.0Ah compact packs often outperform old 4.0Ah bricks. Your goal? One charger + two batteries covering 90% of tasks. Checklist for starter sanity:

- Platform has 12+ tool types (impact drivers, saws, etc.)

- Batteries interchange across all tools

- Compact and high-capacity batteries share the same charger

-

Lithium-Ion Revolution (1990s): Crushing "Short runtime or unpredictable runtime under load" Nickel-cadmium batteries dreaded cold weather and "memory effect" (losing capacity if not fully drained). Lithium-ion, pioneered for power tools in the 2000s, changed everything. No memory effect. 30% more runtime per weight. Faster charging. Crucially, consistent power until dead. That "sudden death" you fear? Modern batteries maintain torque until 1% remaining. Task reality check: A standard 2.0Ah 18V battery drills ~200 3" deck screws in pressure-treated wood, not the vague "long runtime" ads promise.

-

Brushless Motors (2010s): Fixing "Inconsistent clutch performance leading to stripped screws" Brushed motors (still in bargain kits) waste 30% energy as heat, causing erratic speed under load. Brushless motors (using magnets and sensors) deliver precise torque. Why care? When driving finish screws into cabinet faces, brushless drills maintain speed as wood resists, preventing blowouts. They're quieter too (critical for apartment projects). For delicate tasks, this is the difference between professional results and ruined $200 hardwood.

Your Anxiety-Proof Path Forward

Last Saturday, a hesitant beginner swapped to a shorter drill bit and mid-speed clutch setting. Their first straight pilot hole sunk perfectly. We high-fived, and they left with a two-battery kit, not three gimmicks. Momentum matters; the right first steps stick.

The drills of 1917, 1978, and 2010 didn't just add features; they solved user anxiety. Your journey mirrors this:

Phase 1: Start Simple (Like 1917's Pistol Grip)

Define your actual first tasks: mounting shelves? Building planters? Avoid "future-proofing" paralysis. Buy one drill matching those jobs (e.g., a 1/2" chuck compact drill for indoor woodworking). Time estimate: 45 minutes to research task-specific specs vs. stripped screws.

Phase 2: Lock Your Ecosystem (Like 1978's Removable Batteries)

Pick one major platform (18V/20V) with proven backward compatibility. For brand-by-brand battery compatibility details, read our cordless drill ecosystem comparison. Popular brands now guarantee 15+ years of battery support. Never buy a second-brand impact driver, as it fragments your ecosystem. Safety reminder: Test battery compatibility before buying extra tools. Some "cross-platform" claims hide voltage mismatches.

Phase 3: Let Skills Compound (The Modern Era)

After 3 months of drilling, you'll know when to add a hammer drill or 12V precision driver. Start simple, lock the ecosystem, and let skills compound. That Saturday student? They upgraded to a miter saw last month, on the same batteries.

Your Action Plan: End Analysis Paralysis Today

- Audit your next 3 projects: what bits, materials, and tasks will you face? (e.g., 'Hanging 3 heavy mirrors: 5/32" pilot holes in drywall + wood studs')

- Verify platform breadth: does your chosen ecosystem have all tools you'll need in 2 years? (e.g., oscillating tool for trim, circular saw for shelves)

- Grab a two-battery starter kit; prioritize fast-charging (30 min) over raw Ah. Compact 2.0Ah packs handle 95% of DIY tasks.

Confidence isn't about buying the "best" specs; it's about matching tools to your timeline. That first drill isn't a forever commitment; it's the anchor for your evolving workshop. When you hear "cordless drill," think freedom, not fear. The next century of power tool innovation starts with your first clutch click.

Practice on scrap; then commit.